Sausage production is a delicate and precise process that involves a series of carefully orchestrated steps to ensure high-quality, flavorful products. Whether you’re producing sausages for local markets or for global distribution, each stage is crucial for creating a delicious and safe product. Let’s take a closer look at the step-by-step process of sausage production, from the selection of ingredients to the final packaging.

1. Ingredient Selection and Preparation

The first step in sausage production is selecting the right ingredients. The quality of the sausage largely depends on the freshness and quality of these components.

Key Ingredients:

- Meat: Pork, beef, chicken, or a combination of meats is commonly used. The choice of meat will affect the flavor and texture of the sausage.

- Fat: Fat is essential for flavor and moisture. It helps keep the sausage juicy and tender. Typically, fat content is about 20-30% of the total mixture.

- Seasonings and Spices: Salt, pepper, garlic, herbs, and other spices are added to enhance flavor.

- Casing: Sausage casings can be natural (animal intestines) or synthetic (made from collagen or cellulose), which affect the texture and appearance of the sausage.

Preparation:

- The meat is trimmed and ground into smaller pieces.

- Fat is carefully mixed with lean meat to ensure an even distribution, which contributes to a smooth texture.

2. Grinding the Meat and Fat

Once the meat and fat are selected, they are ground together. The grinding process can be done using different sized plates, which will affect the sausage's texture.

Steps:

- The meat is first cut into chunks and placed in a grinder.

- It is then ground to the desired consistency. Some sausages require a fine grind, while others may require a coarse grind for a chunkier texture.

- If the sausage recipe calls for multiple grinds, the meat is passed through the grinder again.

3. Mixing the Ingredients

After grinding, the next step is to mix the ingredients thoroughly. This process ensures that the seasonings, spices, and fat are evenly distributed throughout the meat.

Mixing Process:

- The ground meat is placed in a large mixing machine.

- Spices, salt, and other seasonings are added, and the mixture is blended thoroughly until it forms a homogeneous, sticky texture.

- Some sausages may also require the addition of ice or cold water to help bind the mixture and maintain a consistent texture.

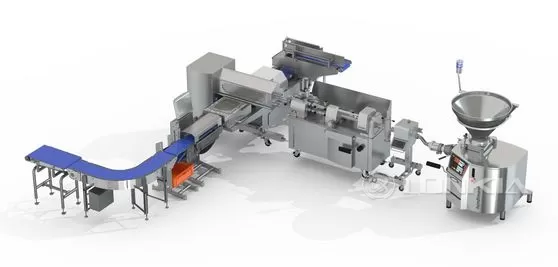

4. Stuffing the Sausage Casings

Once the sausage mixture is ready, it’s time to stuff it into casings. This is one of the most important steps, as it determines the size, shape, and appearance of the sausage.

Stuffing Process:

- The prepared casings (either natural or synthetic) are soaked in water to make them pliable.

- The sausage mixture is loaded into a sausage stuffer, which pushes the mixture into the casings.

- The casings are filled evenly and twisted into individual sausages of the desired length.

- Care is taken to avoid air pockets, which can affect the sausage's texture and shelf life.

5. Linking and Tying the Sausages

Once the sausages are stuffed, they are tied or twisted into links. This helps maintain their shape during cooking and packaging.

Linking Process:

- After the sausages are stuffed, the casing is twisted at regular intervals to form individual links.

- The ends of each sausage are tied with string or clipped to ensure the casing remains securely closed.

- Some manufacturers may choose to use machines that automate this process.

6. Cooking or Smoking the Sausages

Depending on the type of sausage being produced, the next step is cooking, smoking, or both. This step is essential for flavor development, texture, and ensuring food safety.

Cooking Options:

- Boiling or Steaming: Some sausages are cooked in hot water or steam until they reach the desired internal temperature.

- Smoking: Smoking sausages imparts a distinctive flavor and also helps with preservation. Sausages are placed in a smoker, where they are exposed to smoke and heat for a specified period.

- Grilling: Some sausages may be grilled before being packaged, although this is more common for sausages sold fresh.

The goal during this stage is to ensure that the sausages reach a safe internal temperature and are fully cooked without overcooking or drying out.

7. Cooling the Sausages

Once the sausages are cooked, they must be cooled rapidly to stop the cooking process and preserve their texture and quality. Cooling also reduces the risk of bacterial growth.

Cooling Process:

- The sausages are placed in a cooling chamber or a water bath to bring down their temperature quickly.

- This step helps maintain the sausage’s freshness and prevents it from becoming overly dry or tough.

8. Packaging the Sausages

After cooling, the sausages are ready for packaging. Packaging is essential for protecting the product, ensuring its shelf life, and presenting it attractively to consumers.

Packaging Options:

- Vacuum Sealing: Sausages are often vacuum-sealed to extend their shelf life by reducing exposure to air.

- Shrink Wrapping: Some sausages are shrink-wrapped for a tight, secure fit that helps preserve freshness.

- Trays and Film: Pre-packaged sausages are sometimes placed in trays and covered with plastic film for retail sale.

The packaging must also include product information such as nutritional details, ingredients, and expiration dates.

9. Storage and Distribution

Once packaged, sausages are ready for storage and distribution. They must be stored at the proper temperature to maintain their freshness and prevent spoilage.

Storage:

- Refrigeration: Fresh sausages are stored in coolers or refrigerators.

- Freezing: Some sausages are frozen for long-term storage, especially those intended for export or retail distribution.

After packaging and storage, the sausages are ready for distribution to retailers, restaurants, or directly to consumers.

Conclusion

Sausage production is a detailed process that involves selecting quality ingredients, grinding, mixing, stuffing, and cooking or smoking the sausages. By carefully controlling each step, producers ensure that their sausages meet high-quality standards and are safe for consumption. Whether your business focuses on traditional, gourmet, or specialty sausages, understanding the entire production process is key to delivering a product that customers will love and trust.