With the increasing demand for personalization in the fast food industry, the shapes and specifications of meat patties have become more diversified. So, can the meat patty production line support the production of various shapes of meat patties? The answer is yes. Modern meat patty forming machines are highly flexible and adjustable, and can meet the needs of different markets for meatloaf shapes.

Adjustable mold design

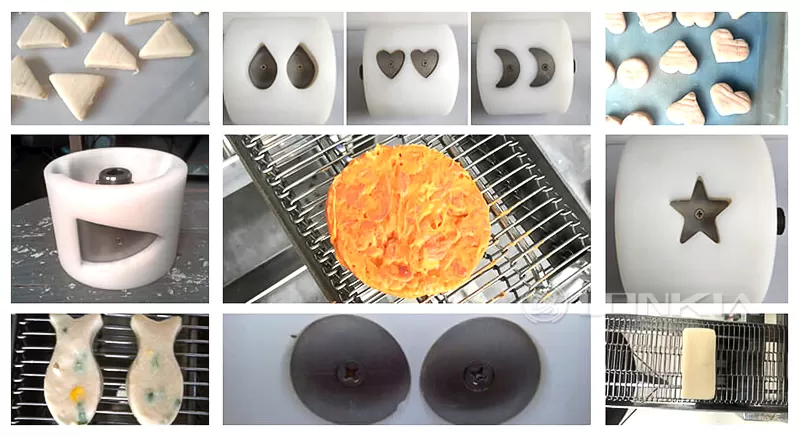

Modern patty forming machines have an adjustable mold design that allows for quick change of different shapes according to production needs. This means that shapes ranging from round and oval to special customized shapes can be achieved by simply adjusting and changing the molds. Users can easily switch between different patty shapes to meet different consumer preferences according to market demand.

Automated molding technology

Automated patty forming technology makes the production process more precise and efficient. The automatic hamburger patty maker is able to ensure the consistency of weight and shape of each patty through an advanced control system. By adjusting the pressure and speed of the molding machine, it is easy to produce meat patties with uniform thickness and standardized shapes, or even combinations of different shapes of meat patties to satisfy different consumers' needs for the appearance and taste of meat patties.

Customized production

In addition to regular round meat patties, modern meat patty production line also supports customized production, and the design of the production line can be adjusted according to customer's needs. For example, the production line can be adapted to different recipes or special consumer needs to create special shaped meatloaf that meets market requirements, such as heart-shaped, star-shaped, etc. This flexible production model allows companies to quickly adapt to market changes and produce a diverse range of meatloaf products.

Efficient production capacity

Modern meatloaf production lines not only support a wide range of shapes, but also offer high production capacity. Thanks to fully automated production processes, large quantities of patties can be produced quickly and efficiently per line. This makes it possible to produce even different shapes of meatloaf in a short period of time to meet mass production needs.

Overall, meat patty production lines are fully capable of supporting the production of various shapes of meatloaf through flexible mold design, automated molding technology and efficient production capacity. This technological innovation not only improves the production efficiency, but also enables enterprises to flexibly adjust the production line according to the market demand and produce diversified meatloaf products that meet consumers' needs. If you are looking for a production line capable of producing meat patties of various shapes, feel free to contact us, the lonkia burger patty forming line is undoubtedly an ideal choice.